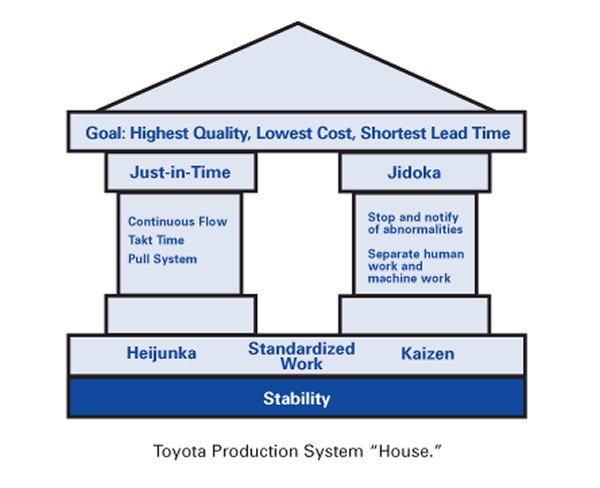

The strictly implementation of Toyota Production System (TPS) to eliminate the muda of over-production ,motion (of operator or machine) , waiting (of operator or machine) ,handling , processing itself ,inventory (raw material) ,correction (rework and scrap) which results in competitive leadtime , cost and quality .

Single piece flow : The implementation of the packaging and conveyance system is one of the important tool for the production in single piece flow system .

Forkliftless Operation : E-Car & Cart is our tool to replace the dangerous Forklift for the in house logistic after implementing the small box and roller concept.

The production system which is running through in one plant from casting production through finishing and machining to get ready Finished Goods give us the good competitive edge.

To maintain the Quality cost delivery at the Top Level in the world as well as to shorten lead time we are using the standard equipments which is standardize among all foundry plants in AT. Group.